ANCEL BST100 Car Battery Tester 12V Battery Analyzer Cranking Charging Circut Test Battery Tester Auto Diagnostic Tools PK BM550

GOOD NEWS:

BST100 Extension Add Portuguese Language

ANCEL BST100 Car Battery Charger Tester Analyzer 12V 2000CCA Voltage Battery Test Car Charging Circut load Tester Car Diagnostic Tools PK KW600

The BST100 Advantage:

1.Simple and easy to use

2.Tests batteries on and off the vehicle

3.Accurate results in milliseconds

4.Battery life analysis

5.Analysis results: Good or Replace

6.Large easy to read LCD screen

7.Test results based on

8.CCA,BCI,CA,MCA,JIS,EN,DIN,SAE,GB and IEC

Standards

9.Quick test - inputs battery volume (AH), then shows battery status

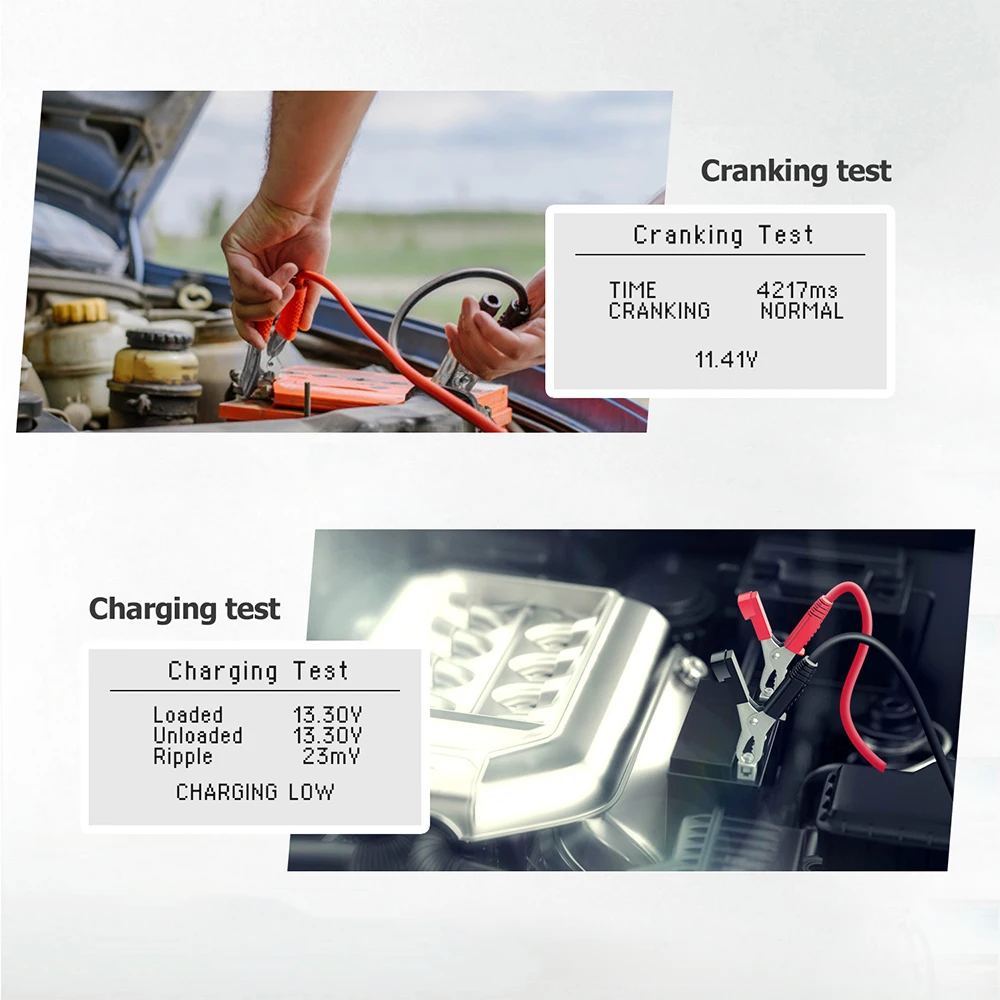

10.Vehicle cranking system test - cranking time, voltage and statu

11.Vehicle charging system test—load voltage, unloaded voltage, ripple status, and charging system status

ANCEL BST100 Function

1.Identify battery status Good or Replace

2.Check Battery Capacity - Cold Cranking Amps (CCA), DIN, EN and IEC information relative to battery rating.

3.Check Internal resistance value (Ohm)

4.Display battery life in percentage (%)

5.Battery Cranking Test, load test

6.Battery Charging Test, Ripple Test

7.Support battery ripple test and review test data

BST100 12V Battery Tester Features

1.Fast and smooth running speed with STM-32 chip set hardware

2.Accurate test results, using high precision amplifier and calibrated by professional battery testing tool, BST100 reading accuracy up to 99%.

3.Wide testing range cover from CCA 100- 2000 , 3- 220 AH, best in the market.

4.Industry initiative graphical battery voltage real time monitoring, can be analysis battery data more accurate.

5.Unique battery results display in percentage and meter mode.

6.Test all automotive cranking lead acid battery, including ordinary lead acid battery, AGM flat plate battery, AGM spiral battery, and Gel battery, etc.

7.Polarity reverse connection protection, reverse connection will not damage the tester or affect the vehicle and battery.

8.Directly test the battery with loss of electricity, no need to full charge before testing.

9.Testing standards include currently the world's majority of battery standards, CCA, BCI, CA, MCA, JIS, DIN, IEC, EN, SAE, GB.

10.BST100 is used to test a wide range of 12V batteries (Starting [SLI], Deep Cycled and Marine) of Wet (Flooded), VRLA or Maintenance Free (MF), Sealed Maintenance Free (SMF), Absorption Glass Mat (AGM) and GEL EPB cell

Software Display:

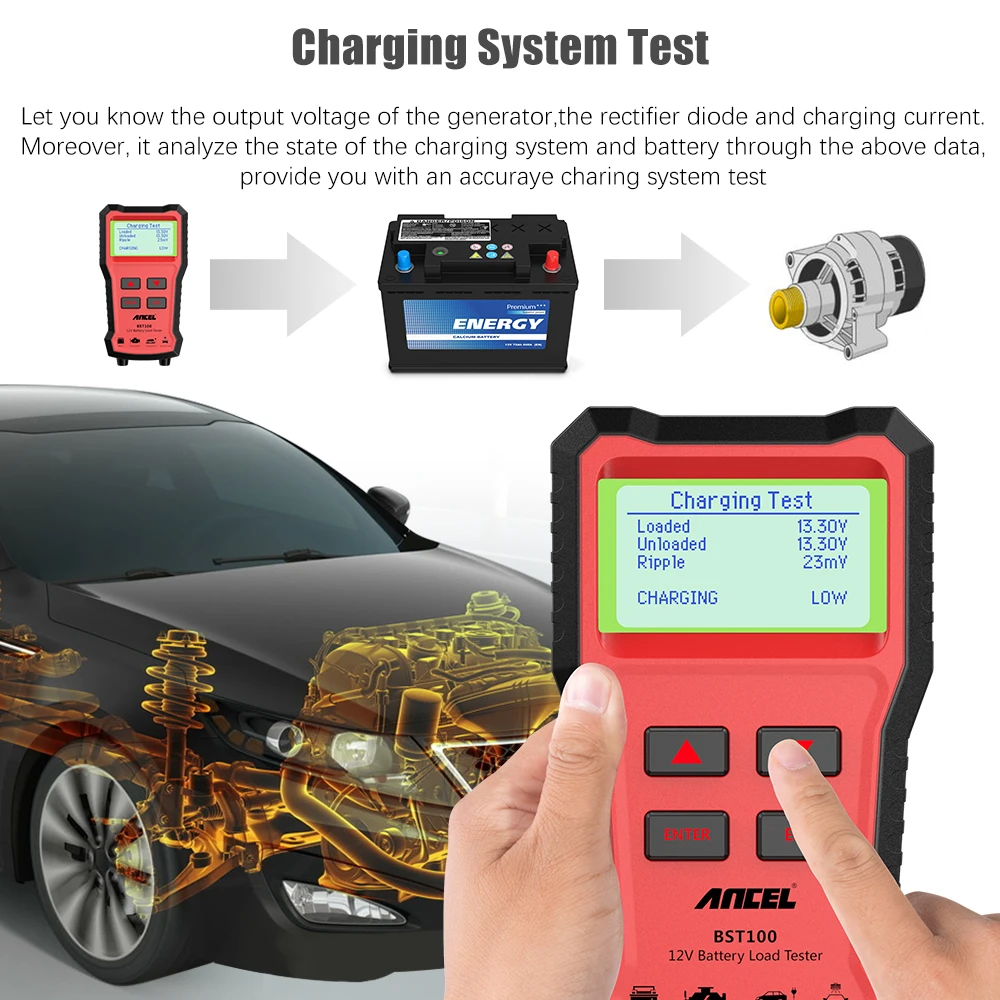

Charging System Test

Let you know the output voltage of the generator,the rectifier diode and charging current.Moreover,it analyze the state of the charging system and battery through the above data,provide you with an accuraye charing system test

Simple And Safe Connection

Builite-in protection device,if connected incorrectly.will not damage the tester

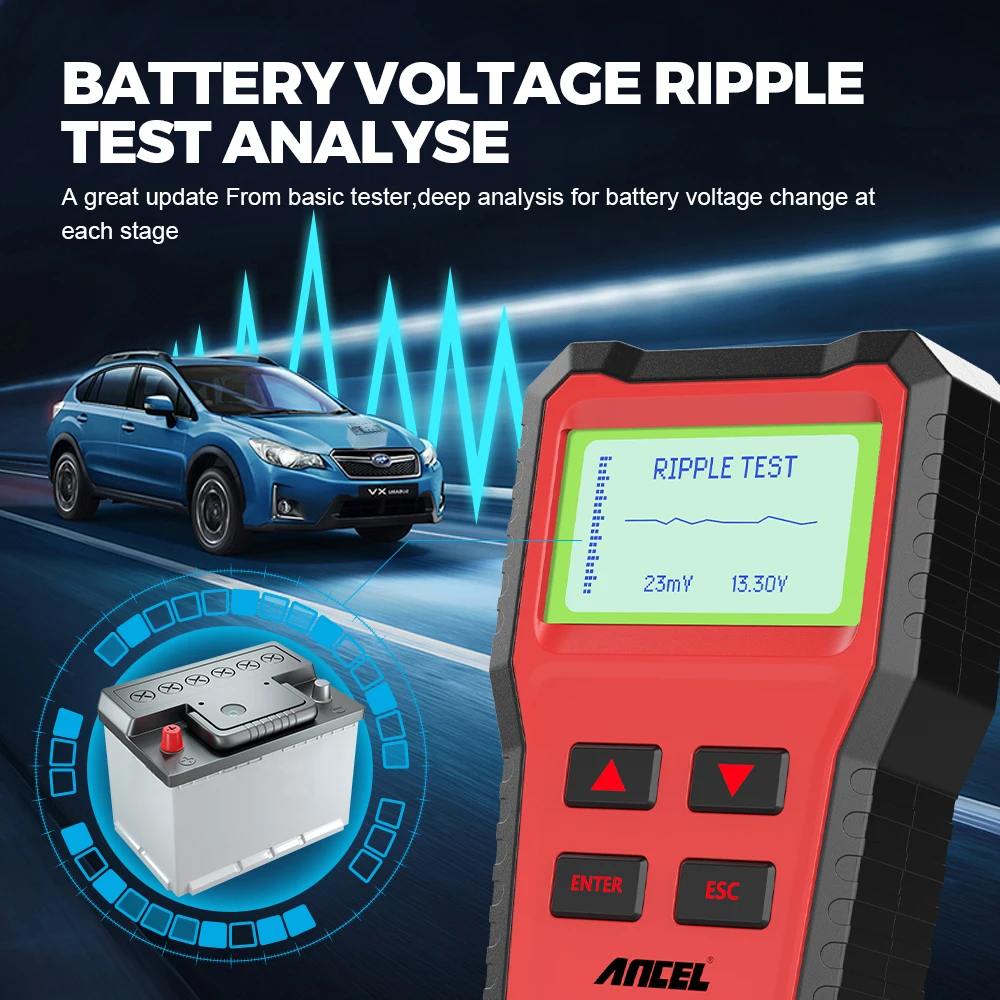

Battery Voltage Ripple Test Analyse

A great update From basic tester,deep analysis for battery voltage change at each stage.

Ancel BST100 Car Battery Tester Application

Use to test a wide range of 12V batteries (Starting [SLI], Deep Cycled and Marine) of Wet (Flooded), VRLA or Maintenance Free (MF), Sealed Maintenance Free (SMF), Absorption Glass Mat (AGM) and GEL cell. The major battery standards JIS, SAE, EN, DIN and IEC are supported.

BST100 Support Languages:

English, Portuguese,French, German, Russian, Spanish, Italian

Excellent Using Experience

The special material of the product provides you with more accurate test results and safe operation

Advantages of this method:

(1) It can be used for checking almost all the batteries including low capacity battery and internal resistance of the notebook battery exclusively.

(2) It will not harm the battery by using this method.

Product Details

Product Package List

FQA 1. What is the measurement principle of this tester?

The battery will gradually be aged with an increase in time. The main reason is that it can no longer generate some effectively chemical reaction because of the aging of the surface of the battery plate. International Electric and Electronic Engineer Association(IEEE) formally looks the Conductivity Test as one of the standards of checking lead-acid storage batteries. It points out from IEEE standard 1118-1996 that: Conductivity Test is used to test AC current generated by putting the known frequency and amplitude AC signal to both sides of the battery. AC conductivity value is the ratio of AC current signal which keeps the same phase with AC voltage and the AC voltage. This tester is designed from this principle actually.

FQA 2. Is the result affected by the installation of negative current for the vehicle?

All the negative currency will affect the result. Therefore please remove the negative currency before checking, to achieve the accurate data.

FQA 3. Can this tester predict when the battery goes down?

The internal resistance of the sealed lead-acid battery is complicated. It is generated by ohm internal resistance, concentration polarization internal resistance, chemical reactions internal resistance and interference effect caused by double capacitance’s charging. The ingredient of internal resistance and its relative content will change with different test methods and different test moments, which can lead to different tested values of the internal resistance. And there is no strict relationship between internal resistance (or conductance) and capacitance of the sealed lead-acid battery. So it is impossible to predict the life of battery according to a single battery’s internal resistance. But it can be predicted the life of the battery will be over soon from the sudden increase of its internal resistance and decrease of its conductance.

FQA 4.Is the CCA value tested by this tester correct?

CCA is considered as a control standard with the produce of the battery. According to the accumulated records, the tested value of a new battery is 10-15% higher than the standard value, and along with consuming the battery, the value is getting close to standard, even lower afterward.

FQA 5.What is the difference between the method used by this tester and the load test method?

The load test method: According to the physical formula R=V/1, test equipment forcibly makes the high permanent DC ( presently 40-80A large current is available ) go through the battery shortly ( about 2-3 seconds). And then the tested voltage of the battery can be used to figure out the internal resistance by the formula.